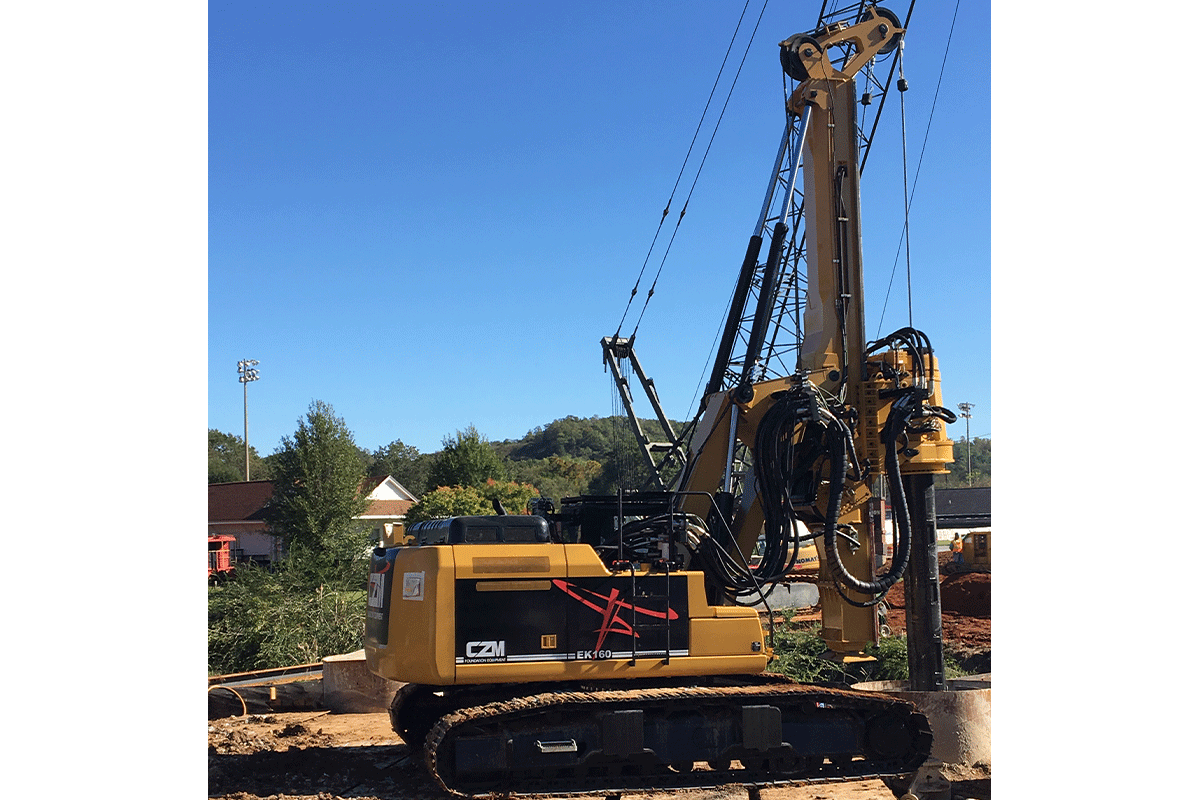

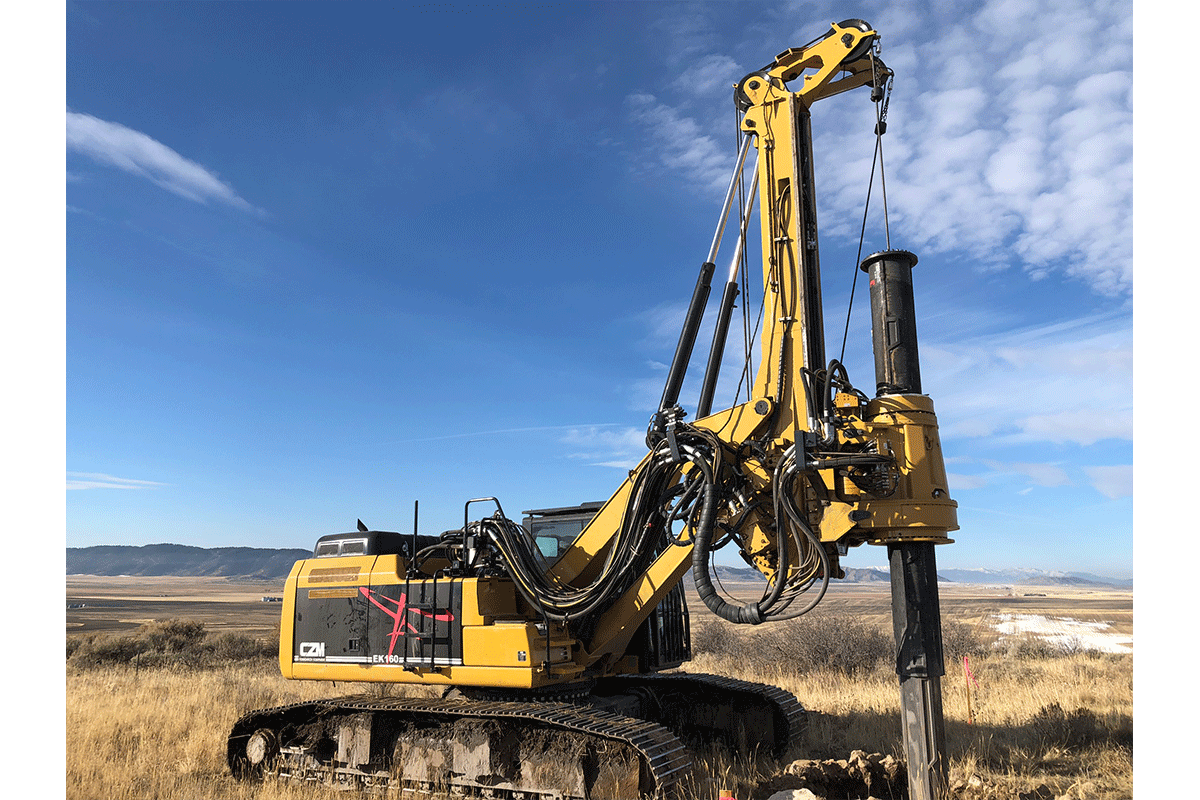

EK160SM

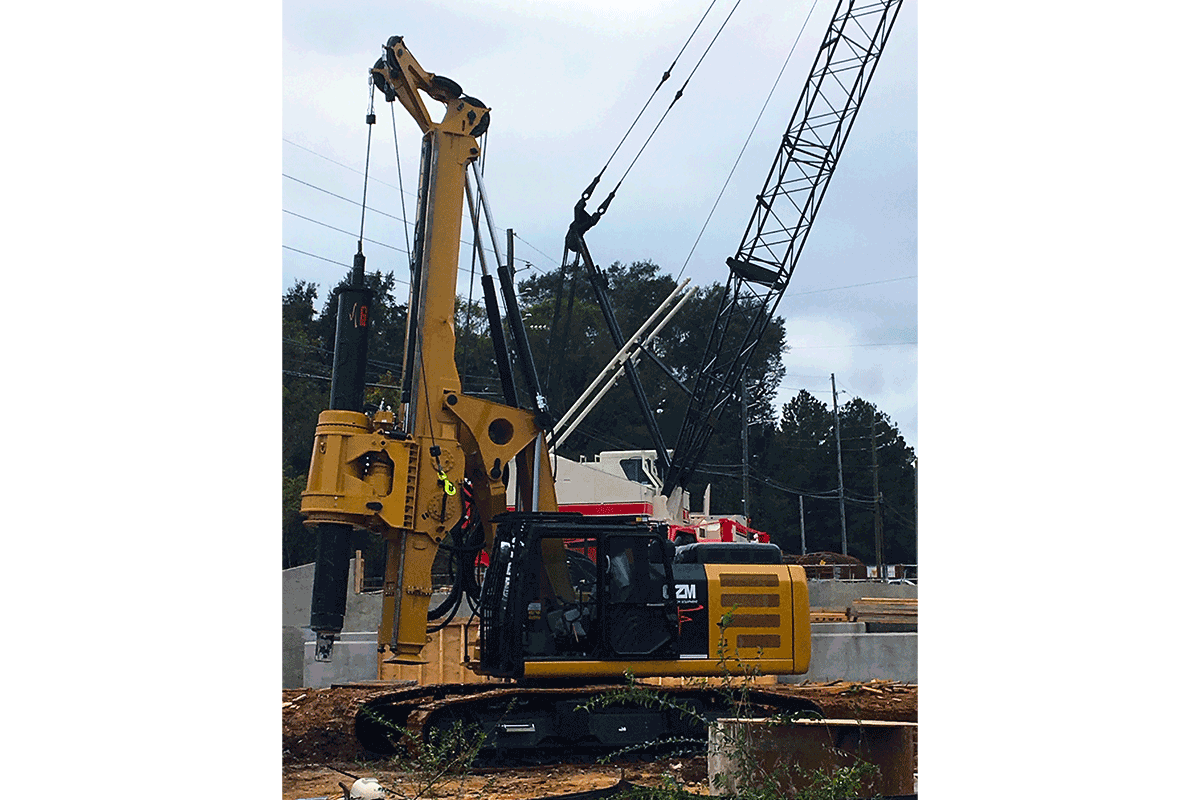

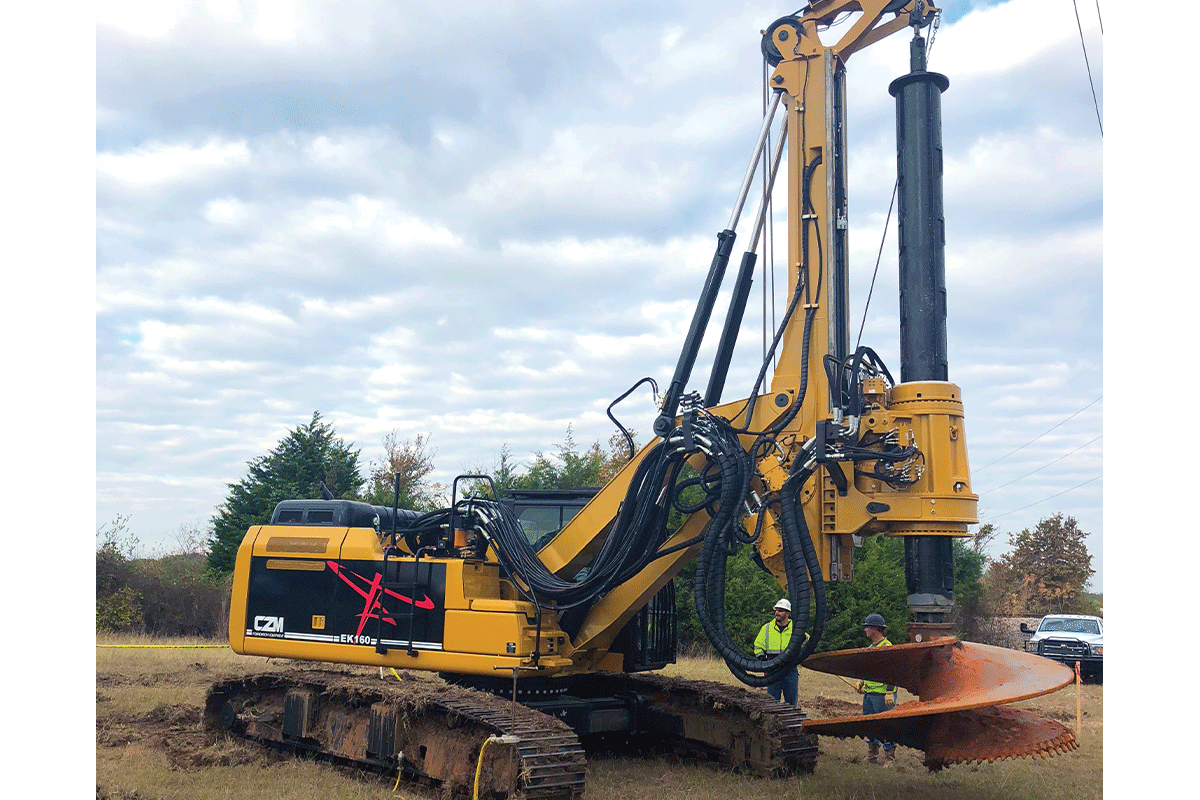

Applications

Kelly Bar

The EK160SM

TECHNICAL SPECIFICATIONS

| Standard Chassis: | Cat® 330 Next Gen | |

| Installed Power: | 275 hp | 205 kW |

| Maximum Torque: | 155,100 ft.lbs | 21,500 kg.m |

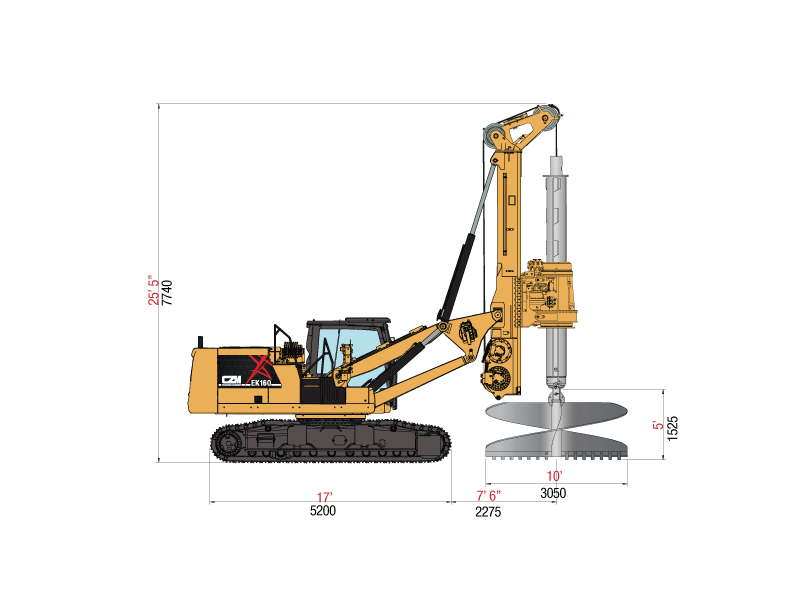

| Maximum Diameter: | 10 ft | 3,050 mm |

| Std. Depth Interlocking Kelly (4 El.) | 45 ft | 13,700 mm |

| Crowd Force: | 44,220 lbf | 20,100 kgf |

| Crowd Cylinder Stroke: | 9 ft 6 in | 2,900 mm |

| Main Winch Line Pull: | 41,000 lbf | 18,600 kgf |

| Operation/Transport Weight: | 96,000 lb | 43,500 kg |

Learn More

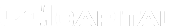

About the EK160SM

The EK160SM is a cylinder crowd drilling rig mounted on a Cat® 330. It is CZM’s most popular model and can be easily converted from Long Mast to Short Mast. It is the most powerful one load machine in the market, with easy set up, completely self erecting.

Base:

- The new Cat® 330 Next Gen powered by a fuel efficient Tier 4 Final C7.1 ACERT engine.

- Equipped with Cat® Vision Link that allows management to monitor machine operations and maintenance data online.

Undercarriage:

- Caterpillar® variable undercarriage VH4400/4300/700. Reinforced frame H style variable undercarriage.

Mast:

- Reinforced mast, with high resistance steel Weldox 700.

Main Winch:

- Special groove for better cable winding and longer cable life.

- Press-roller included

- 2 gears allows for both high speed and high pulling force.

- Automatic gear shifting, for seamless operation, high production.

- Automatic down the hole winch stop.

- Freewheeling winch during crowd operation.

- Hydraulic and mechanical brake.

- Hydraulic measurement of pulling force displayed in the cabin

Rotary:

- Robust design, with 2 slewing bearings on top and bottom, robust pinion and main gear.

- 2 groups of Hydraulic Motor / Planetary Gears for high torque and long life.

- Anti-cavitation, anti-shock and cooling system for longer hydraulic motor life.

- Power-shift for High spin-off speed (120rpm) for quick discharge of soil.

- 3 operation speeds and 3 spinoff speeds. For high torque and high speeds.

- Automatic gear shifting, for seamless operation, high production.

- Exchangeable keys, bolted. No need to rebuild keys by welding inside the rotary.

- Hydraulic measurement of torque displayed in the cabin for the operator.

Cab:

- AM/FM Radio, Air conditioning/Heating

- ROPS cab & Top protection

- LCD monitor for Engine and Hydraulics computer, with diagnostic system

- CZM Canbus System for Drilling Monitoring with auto functions.

Video Tour

EK160SM

EK160SM

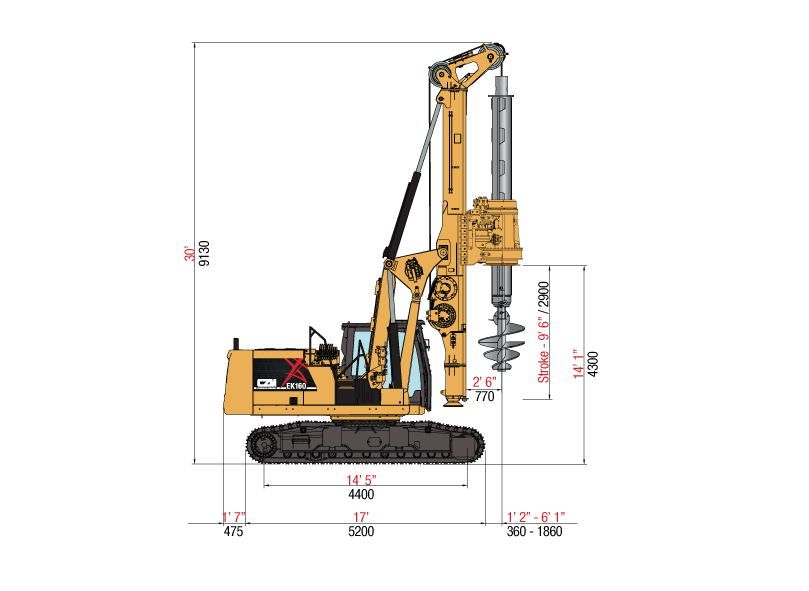

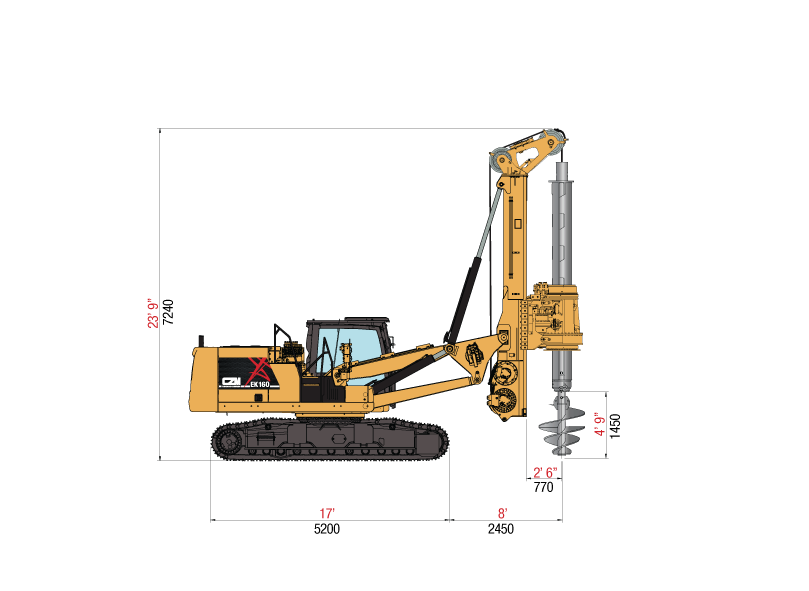

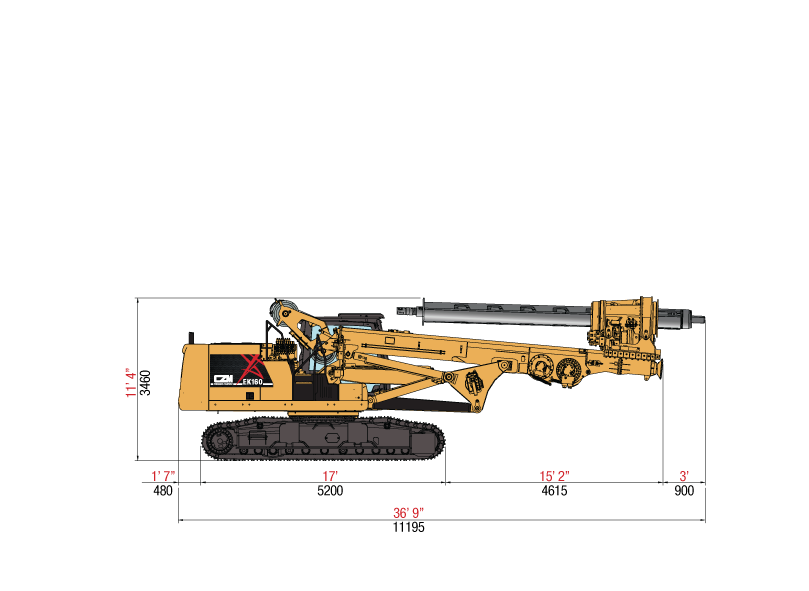

Technical Drawings