EK270LS

Applications

The EK270LS

TECHNICAL SPECIFICATIONS

| Standard Chassis: | Cat® 352 Next Gen | |

| Installed Power: | 443 hp | 330 kW |

| Maximum Torque: | 201,470 ft.lbs | 35,000 kg.m |

| Maximum Diameter | 10 ft | 3,050 mm |

| Standard Drilling Depth: | 90 ft | 27,400 mm |

| Max. Crowd Extraction Force: | 211,125 lbf | 95,910 kgf |

| Main Winch Line Pull: | 63,700 lbf | 28,995 kgf |

| Operation Weight: | 249,600 lb | 113,216 kg |

About the EK270LS

The EK270LS is a full cable crowd drilling rig mounted on a Cat® 352. The long stroke of the rotary makes it ideal for:

- Cased kelly bar drilling with segmented (European style) casing, specially for Secant walls.

- Large Diameter CFA.

- Displacement piles.

- Large diameter single column Soil Mixing.

Base:

- The new Cat® 352 Next Gen powered by a fuel efficient Tier 4 Final C13 ACERT engine.

- Equipped with Cat® Vision Link that allows management to monitor machine operations and maintenance data online and wireless, providing information such as location, hours, fuel usage, idle time, event codes and maintenance schedule.

Undercarriage:

- Caterpillar® variable undercarriage VH5440/4900/900. Reinforced frame H style variable undercarriage. Length between wheels 5440mm, Transport width 3500mm, Operation width 4900mm, Shoe width 900mm.

Mast:

- Reinforced mast, with high resistance steel Weldox 900.

Main Winch:

- Special groove for better cable winding and longer cable life.

- Press-roller included.

- 2 gears allows for both high speed and high pulling force.

- Automatic gear shifting, for seamless operation, high production.

-

Automatic down the hole winch stop. When Kelly bar reaches the bottom of the hole, winch automatically stops.

-

Freewheeling winch during crowd operation.

-

Hydraulic and mechanical brake.

-

Hydraulic measurement of pulling force displayed in the cabin for operator.

-

Swivel and Limit switch.

Rotary:

-

Robust design, with 2 slewing bearings on top and bottom, robust pinion and main gear.

-

3 groups of Hydraulic Motor / Planetary Gears for high torque and long life.

-

Anti-cavitation and anti-shock system for longer hydraulic motor life.

-

Cooling system for hydraulic motors and gearboxes.

-

Power-shift for High spin-off speed (120rpm) for quick discharge of soil.

-

3 operation speeds and 3 spinoff speeds. For high torque and high speeds.

-

Automatic gear shifting, for seamless operation, high production.

-

Exchangeable keys, bolted. No need to rebuild keys by welding inside the rotary.

-

Hydraulic measurement of torque displayed in the cabin for the operator.

Cab:

- AM/FM Radio, Air conditioning/Heating.

- ROPS cab & Top protection.

- LCD monitor for Engine and Hydraulics computer, with diagnostic system.

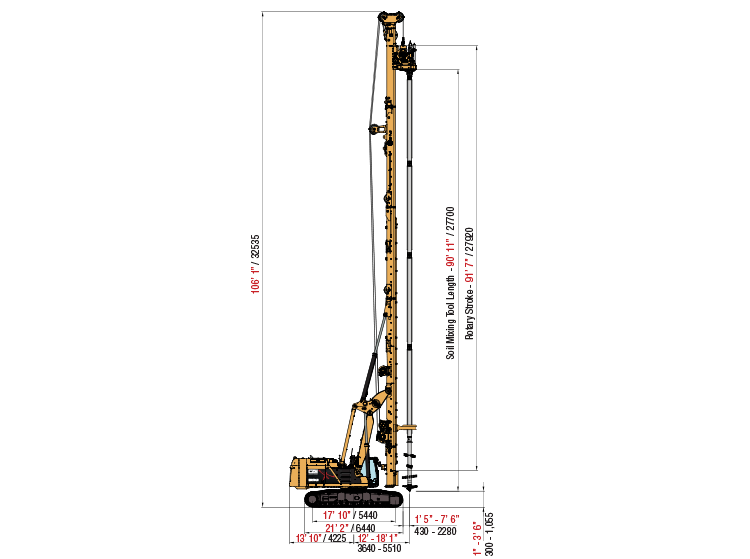

Technical Drawings