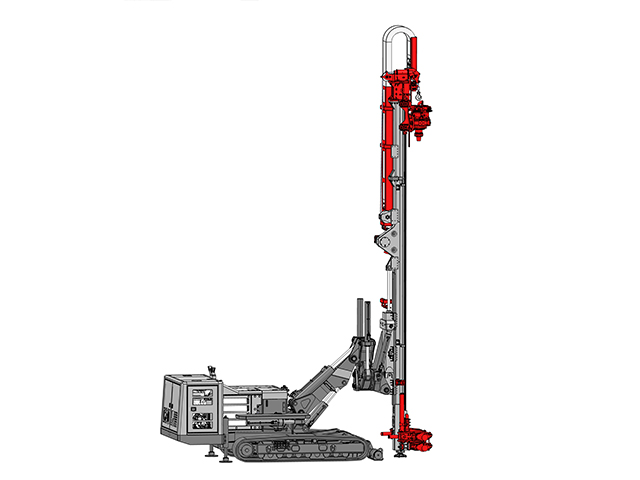

CR18

Applications

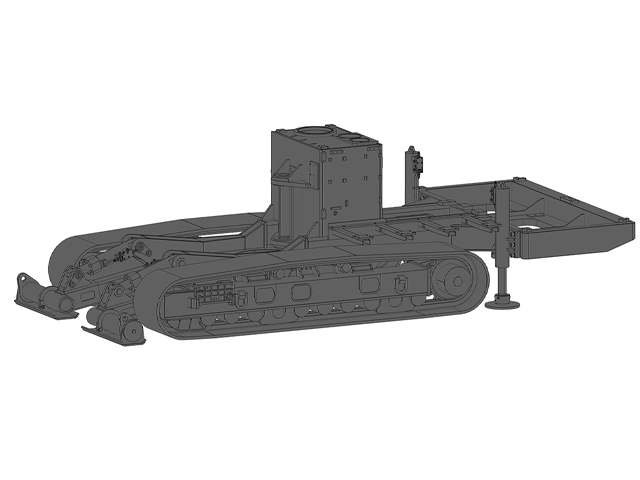

The CR18

TECHNICAL SPECIFICATIONS

| Standard Engine: | Cummins B6.7 | |

| Installed Power: | 310 hp | 231 kW |

| Standard Rotary Torque: | 23,600 ft.lbs | 32,000 kN |

| Rotary Speed | 82-168 rpm | 82-168 rpm |

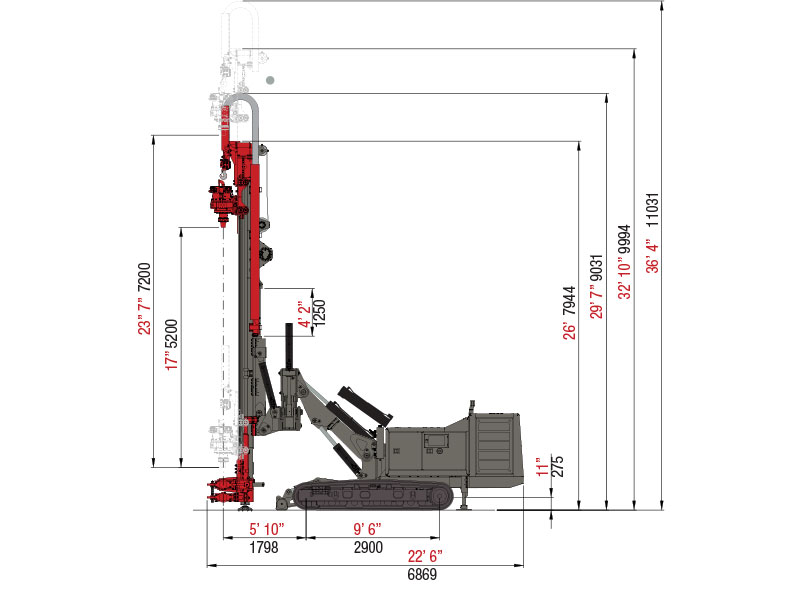

| Single Pass Stroke: | 23 ft 6 in | 7,200 mm |

| Feed/Extraction Force: | 27,000 lbf | 12,000 DaN |

| Double or Triple Clamps (Optional) |

9.4 in; 14 in; 18.5 in; 24.4 in |

240 mm; 355 mm; 470 mm; 620 mm |

| Control | Radio Control | |

| Transport Weight: | 53,131 lb | 24,100 kg |

About the CR18

Reliability; Robustness and Productivity

The CR18 is the ideal response to market needs, the target of CZM’s expert designers was to obtain an advanced drilling rig that stands out from competitors. The CR18 was designed with the clear idea of being the evolution of technology for micropile drilling machines.

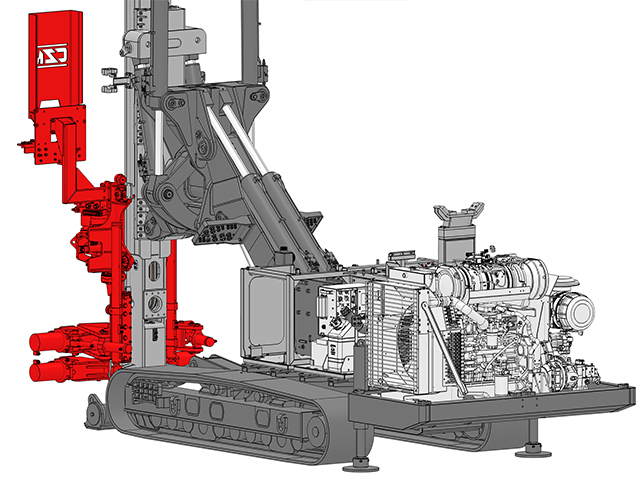

It turns out to be a drilling rig with “imposing” shapes, maintaining fast and precise mobility, equipped with a powerful engine which, thanks to the power management system (PMS) and the optimization of the hydraulic system, obtains the ideal use of engine power, reducing fuel consumption by up to 30% and guaranteeing very high productivity.

The innovative servo-assisted proportional hydraulic circuit and the high hydraulic oil flow guarantee flexibility in the equipment for installing different types of rotary heads and rotary drifters, including double rotary, and always guarantee the declared power without performance reductions.

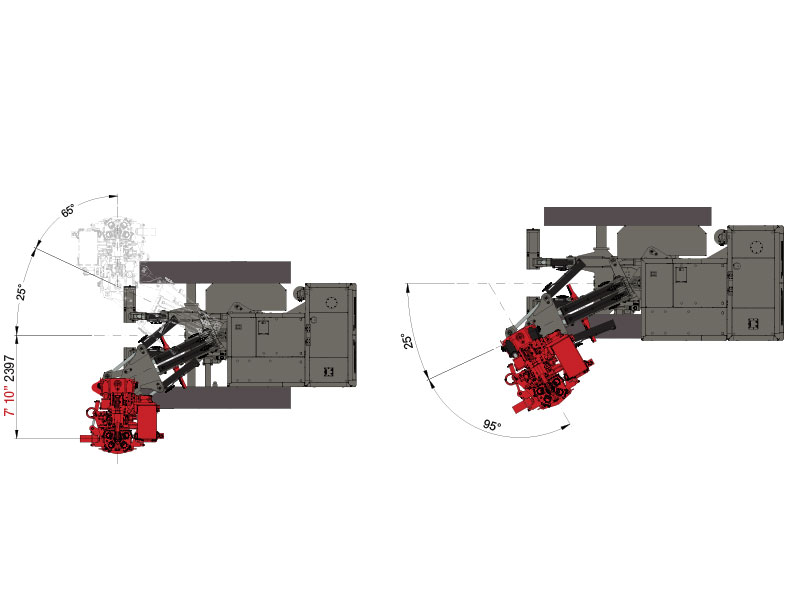

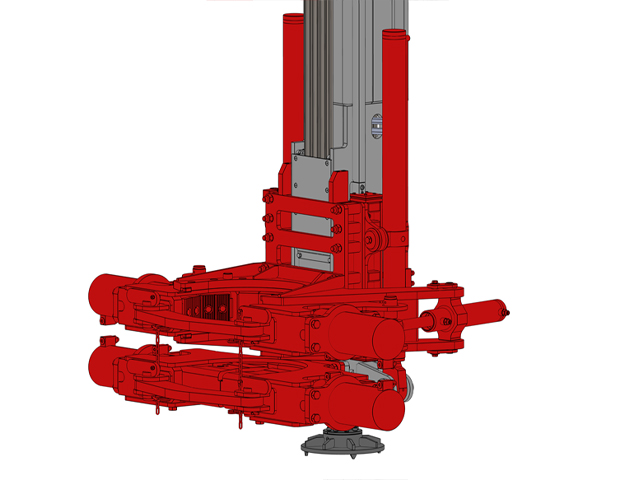

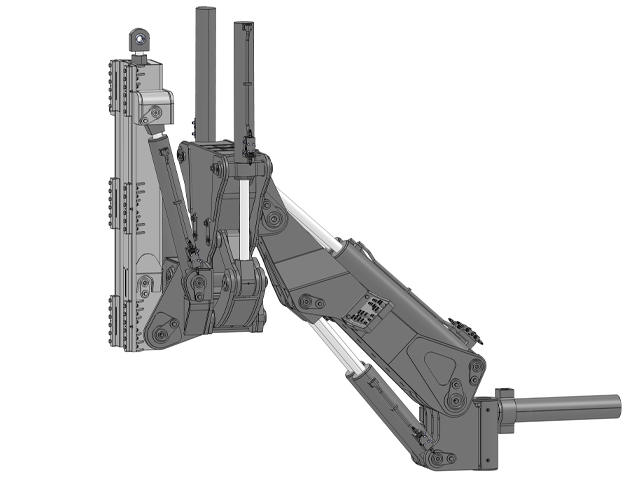

Articulation:

-

In addition to its larger dimensions, all parts are made in high-yield strength Weldox steel.

-

Double boom cylinders ensure safety and efficiency also in more challenging articulation positions.

-

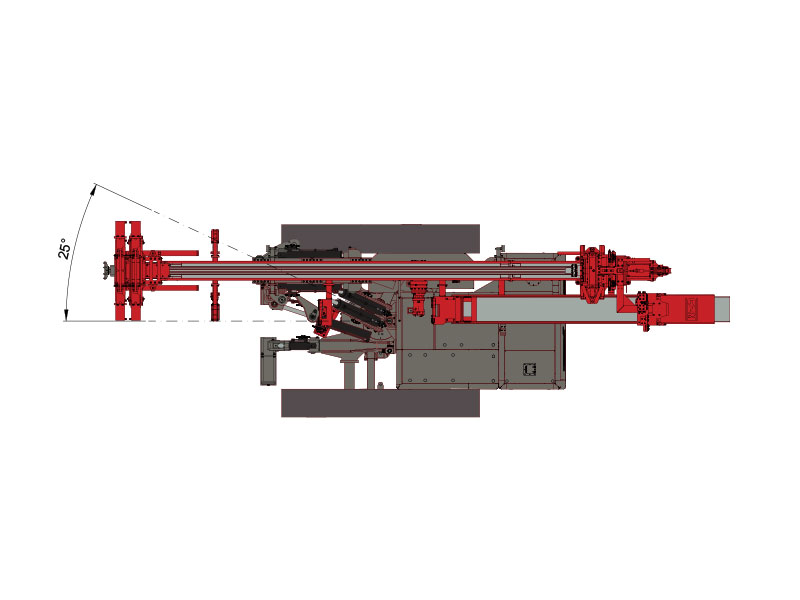

The Front of the Wall guarantees a continuous movement of +/- 93°.

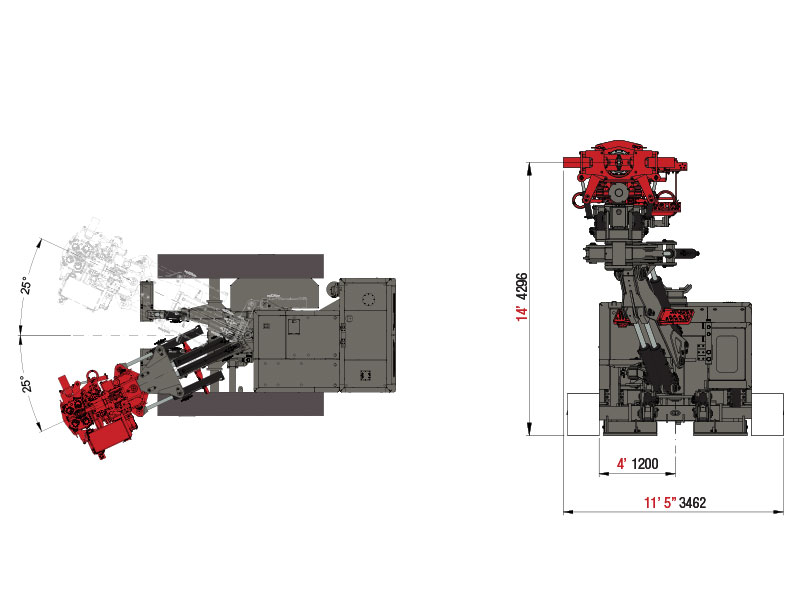

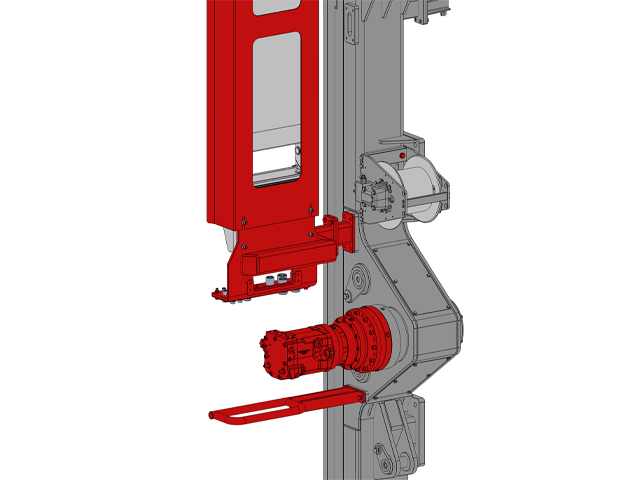

Mast:

The Mast is modular and built with high-yield strength Weldox steel, guaranteeing extreme safety in all working positions.

- Easy to modulate, crowd-pull-back system is integrated into the base mast and has a maximum pull-back force of 12t (27,000 lbs).

- Sliding Clamps with 1000mm (3ft 3in) stroke and pull-back force of 15t (33,700 lbs) can install double or triple clamps with a maximum diameter of 18.”

Engine:

310HP engine equipped with PMS for reducing fuel consumption and emissions.

- Full Load Sensing power system operates the hydraulic system according to the drilling requirements to decrease maximum consumption by maximizing system efficiency.

- 11” touch screen for all machine setting operations.

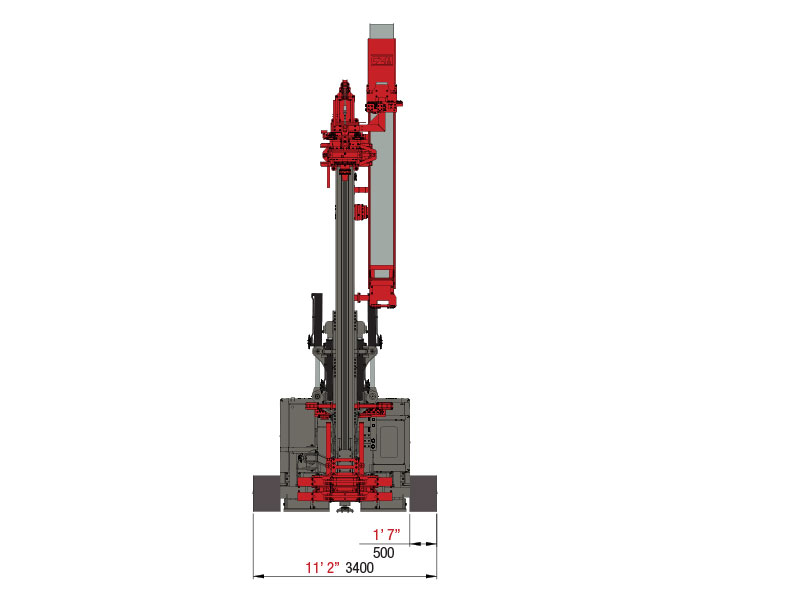

High Stability:

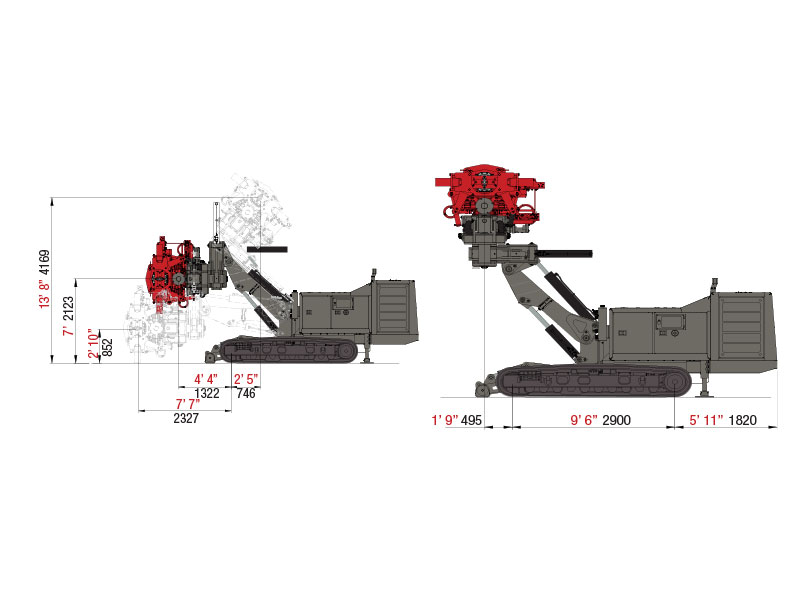

In the design phase, particular attention was paid to the machine’s stability both during translation and during the drilling phase, above all during the execution of tie-backs with the mast transversal to the undercarriage.

A generous over-dimensioning of the structural parts, and the telescopic expandable tracks, guarantee safety and maneuverability, even with lattice extensions for the execution of Jet Grouting injections for useful depths of 22 m (72 ft) during translation, positioning and operation movements.

High Tech:

The electronic system allows you to manage the entire control of the machine itself, for example:

- General telematics

- Fault diagnosis

- Maneuvering speed customization

- Active security

- Passive safety

- Remote real-time control

- Remote control management

The machine is managed entirely by the latest generation Radio Command with a color display.

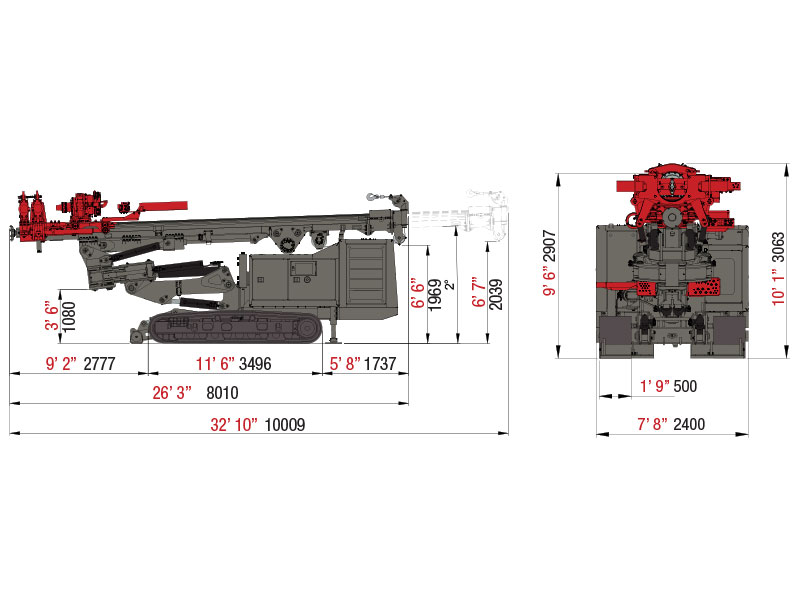

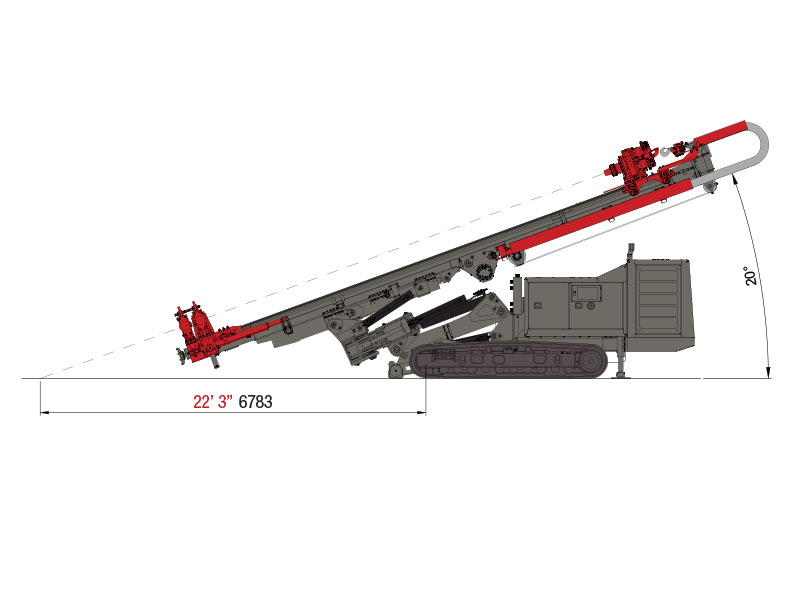

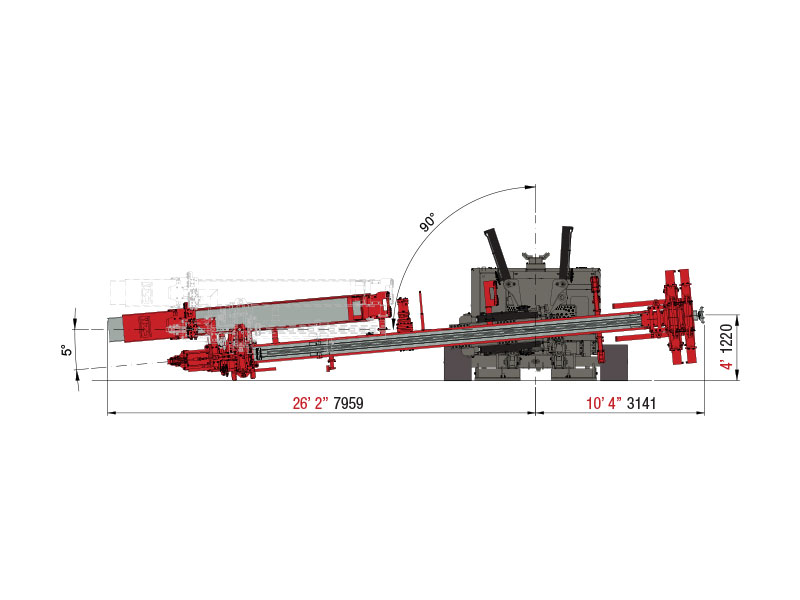

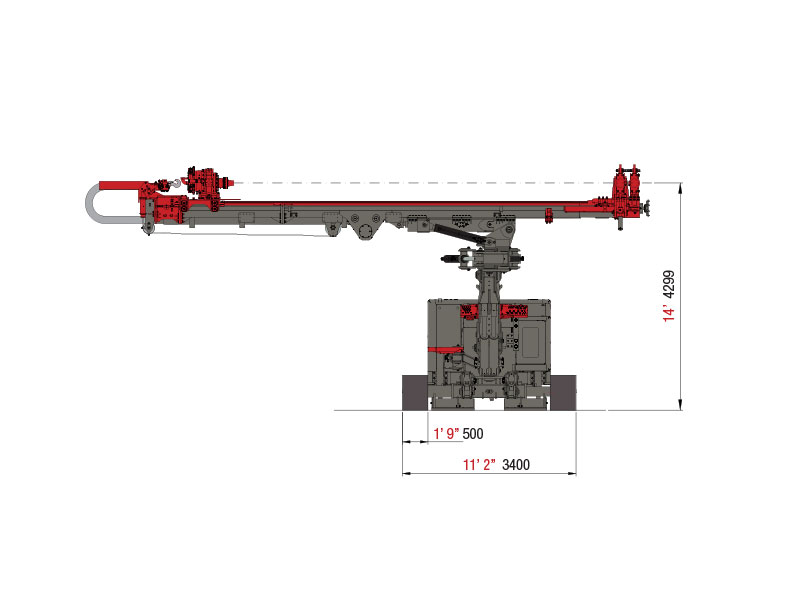

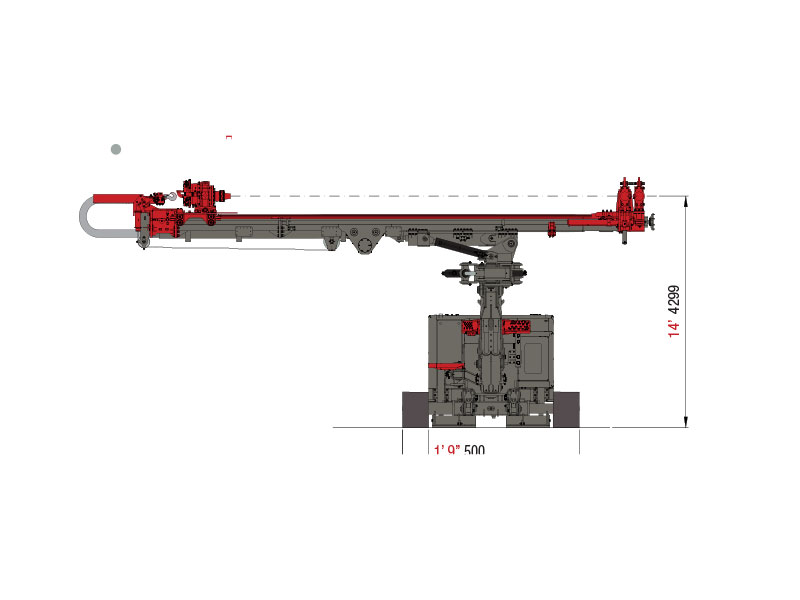

Technical Drawings